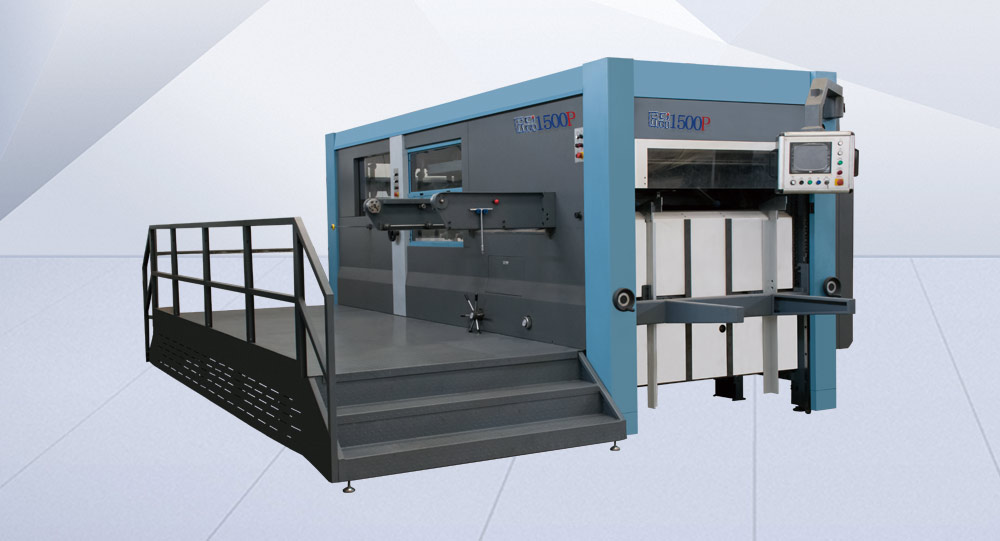

| Model | JP-1500P |

| Max. Die-cutting Speed | 4000 sheets/h |

| Die-cutting Precision | ±0.25mm |

| Max. Die-cutting Pressure | 250T |

| Max. Paper Size | 1500×1100mm |

| Min. Paper Size | 550×450mm |

| Max. Die-cutting Size | 1490×1090mm |

| Paper Processed | |

| Corrugated Paper | ≤8mm (max. thickness) |

| Total Power | 17.5KW |

| Weight | 18T |

| Dimensions | 6800×2600×2500mm |

Front lay: Adopt monolithic front lay, to lower the impact of the paper to keep the accurate of die cutting

Side lay: Special designed side lay, combine with push and pull, adjust freely according to the products, no need changing parts, small paper movement and high accurate of die cutting.

Gripper Bar, Die cutting chase, steel plate, transmission organ, mail machine base, moveable up and down plate, Indexing device, Pneumatic clutch.

Gripper Bar: Adopt hard aluminum alloy to make the gripper bar, strong and light, can deliver the paper stable under high speed.

Die cutting steel plate: Use 65Mn steel plate under special heat treatment, good surface, high hardness, and long life.

Transmission organ: Newly designed transmission organ make sure high speed and accurate die cutting. Worm and worm gear cooperates with crankshaft and connection rod, reducing the moving clearance and avoiding impact between worm and worm gear. Pneumatic clutch and brake are sensitive and reliable.

Indexing device: Adopt high precision parallel trinary cam dividing mechanism, Unique designed cam curve make sure the gripper bar runs more stable.

It’s high efficiency for stripping of front margins and the middle wastes. The stripping die plate is combined with centre location system, automatic clamping. Stripping mode can be easily chosen.

The rear non-stop sampling mechanism and side jogger ensures orderly and tidy delivery of paper. It is able to achieve continuous delivery in the running time. When meets the limit, it will warn automatically to the operator to change the paper delivery plate.

Motor: the main motor adopts Japanese FUJI transducer electrode less variable-speed control. Save energy and low noise. Main paper feeding motor and paper delivery motor adopt China Taiwan electromagnetic brake reducing motor. It is very safe with long life and low noise.

Forced Lubricating System: It is easy to adjust the pressure and flow of the oil. Ensure the oil supply in the main transmission.

Service Hotline:

Service Hotline:Address: Changsheng Street,Economic and Technological Development Zone,Yutian County, Hebei,China

Tel:+86-315-5316188

Mail: info@laizhangjx.com

Web: www.tsjiangpin.com

Mobile Station