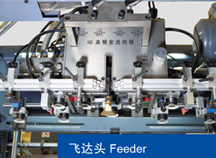

※ High efficiency feeder adopt four suckers and four delivery,the feeder height and angle of suction nozzle can be adjusted easily,ensures smooth and fast feeding.

※ It adopts plc computer program control and man-machine touch screen, which can dynamically detect and display the running state of the machine.Easy adjustment and fast troubleshooting.

※ Front lay positioning adopts straight line,the precision of front lay can be adjusted any time and test paper in place, to ensures high precision of registration and die-cutting to avoid waste.

※ Adopt hard aluminum alloy to make the gripper bar, strong and light, can deliver the paper stable under high speed. Add adjustable device for front and back positioning of gripper bar,positioning accuracy of gripper bar can be compensated by adjustment due to the wear error of main chain or parts.

※ Side lay positioning combine with push and pull,adjust freely according to the products, no need changing parts,small paper movement and high accurate of die cutting,and optional photoelectric detection positioning accuracy.

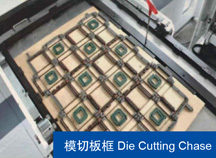

※ Die - cut steel plate use imported high - strength, high - elastic and high - manganese spring steel, good surface, high hardness, and long life.

※ Japan gripper driving chain,matched by prestressed tension,ensure the precision of each set of gripper bar chain.

※ Adopt the ternary cam intermittent structure of 240-degree long motion angle to make the gripper runs more smoothly.

※ The main drive adopts frequency conversion speed regulation, pneumatic clutch, stable braking, quick clutch, safe and reliable.

※ Automatic voltage regulating structure adopts electric digital display, and with accurate and stable adjustment.

※ Forced automatic lubrication ensures normal oil supply of main drive and automatic stop without oil.

※ Timing lubrication system is connected with PLC touch screen display,automatic control of each lubrication point for timing and quantitative oil lubrication.

※ The main oil system adopts unique clean filtration system to make lubricating oil cleaner and smoother.

※ Section adjustable brush and paper stretch blower to stabilize the finished products

※ Hot stamping system is more user-friendly, operation is more convenient.

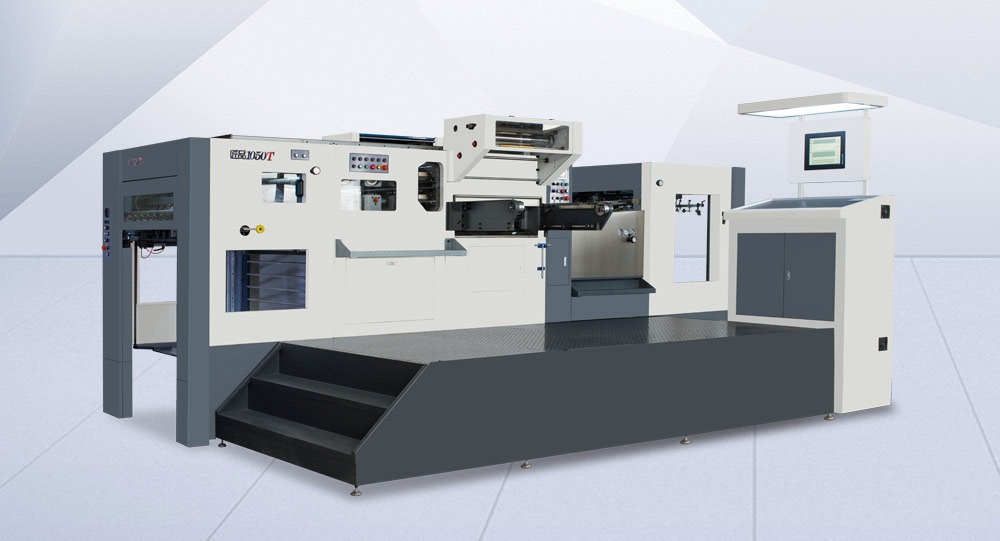

| Model | JP-1050T |

| Max. Speed | 7500 sheets/h |

| Max. Stamping Speed | 6000 sheets/h |

| Max.Paper Size | 1100×760mm |

| Min. Paper Size | 400×360mm |

| Max. Stamping Size | 1080×740mm |

| Max. Die Cutting Size | 1090×750mm |

| Paper Thickness |

Paper(Cardboard):0.1-1.5mm Corrugated(Corrugated board):≤4mm |

| Max. Working Pressure力 | 260T |

| Total Power | 36kw |

| Total Weight | 16.5T |

| Overall Dimensions | 5780×3900×2150mm |

PLC control and touch screen are adopted to monitor the running state of the machine.

Equipped with alarm device to remind others to pay attention to safety.

Equipped with multiple button plate,realize control of different units of the machine,easy to operate and reduces the working intensity.

Multiple safety switches ensure safe operation.

Stamping unit: adopt the most advanced stamping system driver software.

Japan Fuji servo motor device.

Three separate heating plates to reduce stress variation.

Main drive adopts large modulus worm gear,worm drive,positioning by shaft and connecting rod,bearing bush form connection by hand grinding, reduce the movement gap,it can keep the machine running smoothly at high speed.

Adopt the ternary cam intermittent structure of 240-degree long motion angle to make the gripper runs more smoothly at high speed and die cutting precision.

Pneumatic automatic lock plate positioning, repeated positioning accurate, easy to operate.

Automatic pressure regulating structure adopts electric digital display, easy to realize die cutting pressure adjustment.

Pneumatic automatic lifting frame, convenient and fast.

Double sheet detection controller, effectively control double sheet, reduce waste.

Professional paper belt, stainless steel paperboard with high abrasion resistance pressure paper rubber roller, brush roller, convenient adjustment.

Equipped with photoelectric detection device, it can adjust the precision of any front lay and paper in place at any time to avoid waste.

Paper adjustment hand wheel is equipped,to adjust paper delivery time,make it match with die cutting unit.

Adopt European technology four suckers and four blowers,cardboard, corrugated dual-purpose feeder.The suction head can adjust all kinds of suction angle and air volume to make the suction paper more stable.Realize transfering paper accurately and smoothly for both thick and thin paper.

Die-cutting chase double reinforcement, pneumatic locking.

Steel plate air float, saving time and effort, convenient and fast.

Equipped with imported vacuum pump to make paper separation and delivery more reliable.

Adopt the 240°ternary cam intermittent mechanism indexing, circular cog belt transmission,make gripper bar smooth running,ensure die cutting precision, improve the service life of the machine.

Equipped left and right side lay,and with push and pull two functions, convenient and fast to switch.

Service Hotline:

Service Hotline:Address: Changsheng Street,Economic and Technological Development Zone,Yutian County, Hebei,China

Tel:+86-315-5316188

Mail: info@laizhangjx.com

Web: www.tsjiangpin.com

Mobile Station